Structural sheds used in industries to store raw materials or for product manufacturing, known as Industrial Sheds. These Commercial sheds are used for warehouses, factories, godowns, workshops, storage plants etc. Industrial Shed can be small or big in size depending on the requirement. Various steps are involved in Industrial Sheds Design like Site Inspection, Planning, Design, Components Fabrication, Installation etc but the most important step is Components fabrication, which should be of best quality for gaining and maintaining the standards, endurance and various other benefits of an perfect industrial shed.

Hindustan Alcox Limited is one of the steel fabricators in India which not only at its best on producing the best quality of steel, but also specializes as an Industrial Sheds Manufacturer in India in the last few decades. One of our best creations in the field of industrial building manufacturing is Pre-Engineering Buildings / PEB. With our high commitment to Design, Manufacture and install Pre-Engineered Steel Buildings, we offer hi-tech solutions with highest precision to meet the structural requirements to our customers in the Pre-Engineering Building industry.

Pre engineering building is the low rise buildings build in such a way that its structural parts like columns, purlins, roof truss etc are manufactured prior to its arrival on manufacturing site. As the name suggests itself, Pre-engineered building (PEB) is the building manufactured and constructed using prefabrication process. Pre-Engineered Building is becoming increasingly common nowadays to efficiently satisfy a vast range of adaptive structural applications and aesthetic design requirements because of the diminished amount of pre-engineering involved in custom computer-aided designs (CAD). Generally, Pre-engineered buildings are the low rise buildings, since maximum height can go from 25 to 30 meters. Low rise buildings are best for houses, offices, shop fronts, showrooms etc. Building a pre engineering building could save some of the cost and time spent in its construction. In time saving, PEB construction takes less time since work get divided into different appropriate work sections. But more than ‘Time’ and ‘Cost’, further two other things are of prime importance, as follows:

1.Fit To Purpose: The pre engineering building should be economically and spatially fit to purpose that client want to realize by working under it.

2.Safe for Workers: The labor working under Constructed Pre engineering building should be free from any threat to their lives.

Moreover, the standard of PEB building can be customized by the attachment of windows, doors, trims, eaves, and many other exterior features, resulting into a new creation in field of structural engineering.

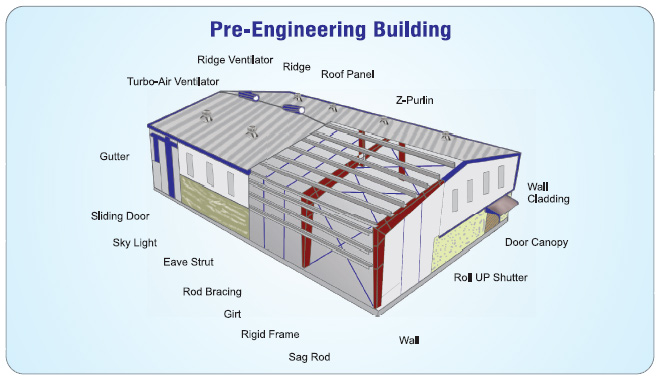

MAIN COMPONENTS OF PRE-ENGINEERED BUILDINGS

Depending on the structural type to be created Pre Engineered Steel Buildings, followings are the major components used in PEBs :

- Primary frames / Main framing

- Secondary frames/ End wall framing

- Roof Sheeting and Wall Cladding

- Structural subsystems

- Foundation and Floor systems

- Other accessories such as sliding doors, roll up doors, windows, louvers, etc

Advantages of Our PEBs

Minimum Foundation Requirement: In the construction of industrial buildings like PEBs, foundation requirement is very less as compared to that in constructing conventional building.

Highly Recyclable: Pre engineering buildings can be recycled without any time or resource wastage. The prior fabrication of its components is responsible for making it highly recyclable.

Robustness: The strength of industrial sheds entirely dependent on the quality of steel used in its components fabrication process. Best quality of steel produced by our company is handy in maintaining the robustness of industrial sheds.

Durability: In structural Engineering, durability of any structure is proportional to its robust nature and its adaptability to adverse environment conditions like temperature, moisture etc. The Steel components produced by the company fulfill both qualities.

Mobility: Industrial sheds are highly movable for one place to another by just uninstalling the components and material used , and then reinstalling them to another place which cannot be feasible in case of conventional buildings.

Reluctant to Welding: There is no need of welding the components with each other but they are just bolted together in the installation phase for the construction of Pre engineering buildings.

Minimum On-Site Construction Time: The construction time needed to build an Factory building in very much less as compared to the construction time needed to construction of other buildings.

Minimum Generated Waste: The time, labor & resources of a company need not be wasted for efficient realization of goal. When It comes to wastage, zero wastage for manufacturing PEBs is one of the quality which differentiate it from other costly structures.

Controlled Quality: In PEB Construction, The quality of steel can also be controlled depending on the client’s requirement. This customization cannot be possible in any other type of structures.

Affordable Price: In this modern era, Most of the clients prefer to build such kind of structures which are not only affordable to them but also takes less time, which can only be fulfilled by Industrial sheds like Pre engineering buildings.

Energy Efficient: The PEB Buildings are very energy efficient, as they can be cooled or heated very easily. According to work requirement, Light colors can be used to reflect sun energy for summers and dark colors can be used to trap heat energy for winters.

Applications of PEBs :

Pre-engineered building has followings major applications and are as follows:

| · Sport Halls

· Aircraft Hangers · Supermarkets · Equipment housing · Telecommunication shelters · Houses · Workshops · Distribution Centres · Commercial Showrooms · Service Buildings

|

· Office Buildings

· Labor Camps · Petrol Pumps · Schools · Factories · Warehouses · Restaurants · Railway Stations · Living Shelters · Community Centres

|

We at Hindustan Alcox Limited, own a firm experience in the industry sheds and PEB solution Providers in a view to understand, predict, & calculate the stability, rigidity and strength of built structures with the potential and dedicated support of our well qualified, trained and experienced team.