Iron ore:

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, deep purple, to rusty red. The iron itself is usually found in the form of hematite (Fe2O3), magnetite (Fe3O4) goethite (FeO(OH)), limonite (FeO(OH).n(H2O)) or siderite (FeCO3). Ores carrying very high quantities of hematite or magnetite (greater than ~60% iron) are known as “natural ore” or “direct shipping ore”, meaning they can be fed directly into iron-making blast furnaces. Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel.

About 98% of world iron ore production is used to make iron in the form of steel.

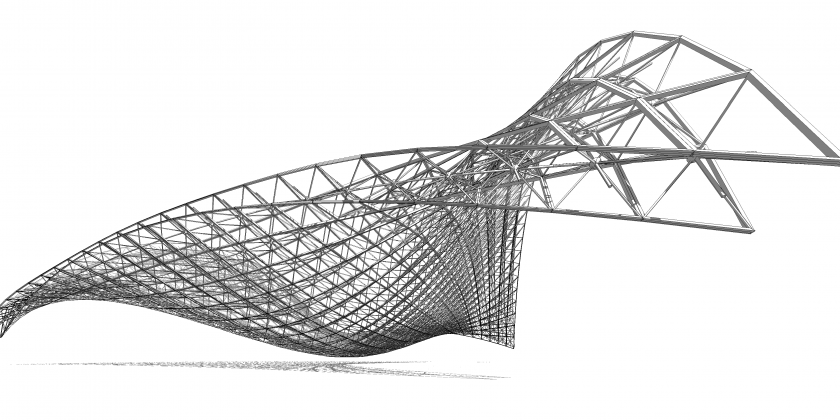

Are you getting problem while storing Coal, Limestone, Clinker, Additive, Lignite & Gypsum coal in cement and power plants, Our Structure is built with a span of up to 150 m and height of up to 40 m. In-house Design Fabrication and erection.

Types of iron ore

MAGNETITE

Magnetite is best known for its property that it is strongly attracted to magnets. Some forms of Magnetite from specific localities are in fact themselves magnets. This form is known as Lodestone, and is the only mineral that acts as a natural magnet. Although its magnetism is weak, it is strong enough to attract large nails. Due to its magnetic properties, small iron particles are often found clinging to its surfaces. Some dealers intentionally place metallic filings on a Lodestone to demonstrate its magnetism.

HEMATITE

Hematite is one of the most common minerals. The color of most red and brown rock, such as sandstone, is caused by small amounts of Hematite. It is also be responsible for the red color of many minerals such as Garnet, Spinel, and to some extent, Ruby. Non-crystalline forms of Hematite may be transformations of the mineral Limonite that lost water, possibly due to heat.

Specifications

The major rock types mined for the production of metallic Iron are massive hematite, pisolitic goethite/limonite, which provide a ‘high-grade’ ore, and banded met sedimentary ironstone, magnetite-rich metasomatite, to a much lesser degree, rocks rich in siderite, rocks rich in chamosite which provide a ‘low-grade’ ore. The pure metal is silvery white, very ductile, strongly magnetic and melts at 1528° C.

High-grade iron ore

High-grade ore generally has a cut off grade of ~>60% Fe. Historically it has provided a direct feed to smelters as either a raw lump or fines, also in a processed form such as sinter or pellets. There are emerging markets for new varieties of feedstock. Examples include sintered iron carbide and ‘DRI’ ore, which is natural ore with Fe >69% and low levels of specific trace elements suitable as feed to ‘direct reduction’ smelters

Low-grade iron ore

Low-grade ore is a term applied to iron-rich rocks with cut-off grades in the range of 25-30% Fe. It was the main supply of iron ore for many centuries of the World’s early history of production of iron. Since the 1950s North America’s main supply has been low-grade or

Steel is a processed form of pig iron with impurities such as silicon, phosphorus and sulphur removed and with a reduction in the carbon content. Globally, steel’s versatility is unsurpassed. Wrought iron (low carbon) and cast iron (pig iron) also have important markets. One of the most ubiquitous products in Australia is corrugated iron, a structural sheet steel shaped into parallel furrows and ridges. It was invented by Henry Robinson Palmer in 1828 in London and quickly became popular for roofing and farm buildings.

Other Well-Known Uses of Iron Ore Compounds are:

Iron sulphate used as fungicide, the oxalate of iron in photographic development, limonite, goethite, hematite as pigments and abrasives, magnetite in the production of industrial electrodes and for washing coal.

Iron chloride and nitrate used as mordents and industrial reagents in the production of several types of inks.

Iron carbonyl as a catalyser of many chemical reactions micaceous hematite as a protective paint on steel superstructures.

Use

Iron Ore accounts for approximately 95% of all metals used by modern industrial society. Metallic iron is most commonly produced from the smelting of iron ore to produce pig iron.

Many of steel industries owners have problem with storing of iron ore

Iron ore storage

We would like to propose Large Span Steel Shed, which can be used to cover iron ore; it can built with a span of up to 150 m and height of up to 40 m.

The construction systems uses mild steel in case of iron ore storage, no welding is required because the connection of the member consists of a very efficient moment-resistant mechanical joint. Iron ore storage shed may be built in single- or double-layer configurations, depending on the load and span. Experience suggests large spans are required in iron ore storage; a-double-layer is the most cost-effective

Iron ore storage sheds are often built over operating stockpiles since construction can proceed without interrupting operations. Because our erection process does not require machines to be installed internal periphery of the span.

Roofing of the structure:

Galvalume is typically use for roofing purpose, Galvalume is lustrous spangled appearance is attractive enough to be used without painting. The GALVALUME sheet is a unique product which is suitable for heating and ventilation applications. It has better resistance towards oxidation and can withstand temperatures up to 315°C without discoloration. This feature of Galvalume enables us to use on limestone shed for roofing purpose.

Key Features

- Smooth Surface and uniform spangled appearance

- Excellent quoting with anti-fingerprint to ensure better appearance and longer life

- Surface treatment as per ROHS (Restriction On Hazardous Substance) norms

- Wider thickness range with tighter tolerances to ensure precision in end-applications

Advantage of Iron ore storage shed:

- For achieving effective prevention and control of potential fugitive emission

- Lesser Operation and Maintenance cost

- Comply with current environmental guidelines by CPCB (Central Pollution control board)

- Protection from weird environmental condition

Conclusion:

Our Structure is fully Complying with new environmental regulations for air quality, Prevention and control of fugitive emission. Instead of investing in temporary solution, it is recommended to adopt permanent solution. Our solutions presented here not only allow affordable compliance, but also enhance the reputation of your plant. In addition, one-time investment is much more economical than the periodic investments

Iron ore storage shed manufacturers in India who provide In-house Design Fabrication and Installation