Multi-Storey Building

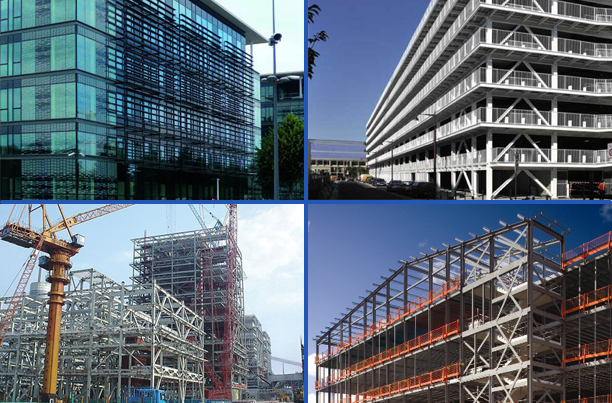

Steel frames construction is a very popular structural form for multi-story buildings as it provides great flexibility.

Structural Principles

The structure must have adequate strength and stiffness to resist the applies loads due to gravity and wind. The function of the structure in resisting vertical loads due to gravity and horizontal loads due to wind is generally considers separately.

Factors affecting choice of structural system

The design should ensure a coordinated approach including structure, envelope, services and finishes. the principal descisions integration of building services, and external wall construction.

Floor Systems

The principal structural elements of a typical multi-storey building are the floors, beams, columns and foundations.

Framing schematics for a Complete building structure

The most common forms of complete building structure in steel construction are the established composite system and the Slimdek system.

Vertical Bracing Systems

A variety of structural forms can be used to provide lateral stability. the principal systems are shear walls, lattice frames and rigid frames, but more sophisticates systems may be needed for very tall buildings.

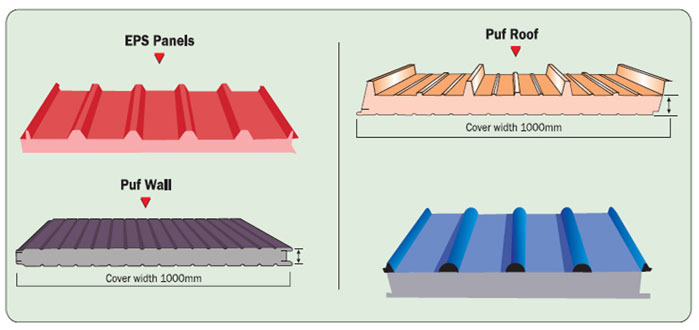

COMPONENTS & ACCESORIES

Modern steel buildings comprising of light weight steel components and wide span and its optimized design of steel reduces,weight,while meeting all design criteria requirements. It is most economical and suitable solution for Modern era Building needs.

Combination of PEB Components with Civil Construction to make prefabricated buildings having major applications such as industrial sheds, canopies, warehouses etc. It is the most common, economical,light weight, timely completion solution to common building needs.

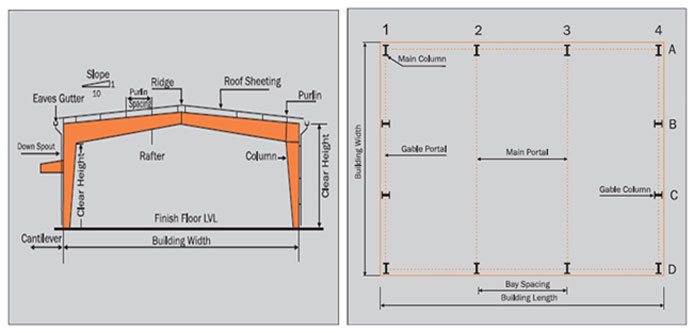

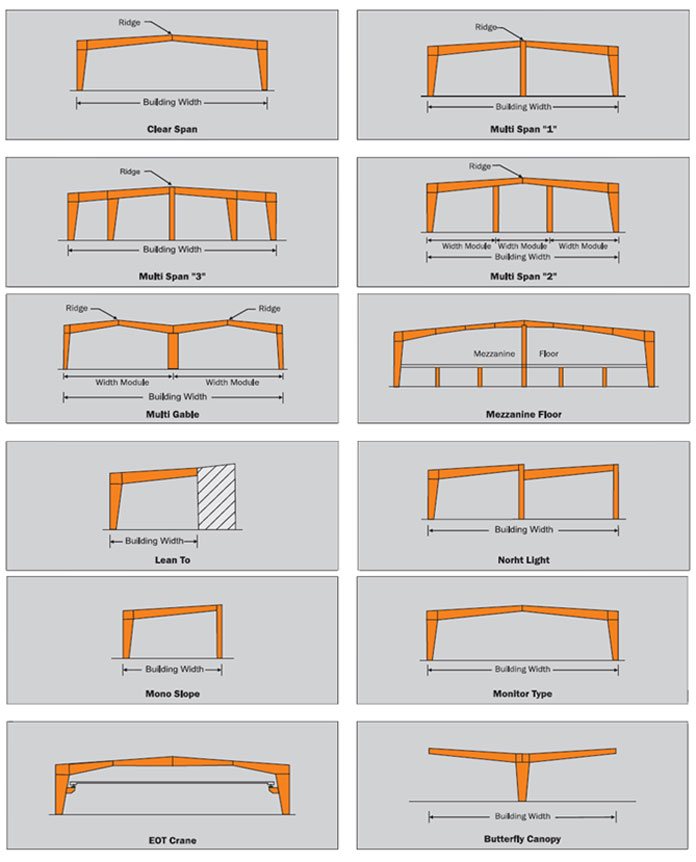

Main Frame

Frames in the PEB industy often refer to primary built-up & hot rolled members. Constant depth or tapered depth built-up members generally account for over 90% of the weight of frames while hot rolled members generally account for the remaining 10%

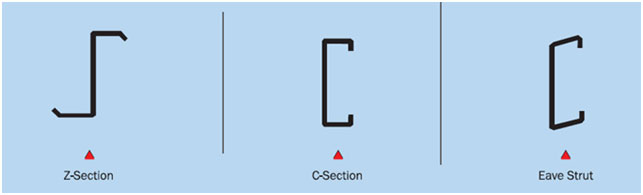

Secondary Members

These are Light Weight, Cold rolled Hi-Tensile steel, Low Cost,Economical, eadily fatricated Purlins commonly used in PEB, PREFAB Buildings having wide applications area such as industrial sheds, canopies, warehouses etc. It is the most common, economical,light weight, timely completion solution to modern building need. Eave struts located at the building eaves (corner of roof and wall sheeting along sidewalls also providing bracing for frames and supporting roof and wall panels.

Metal Decking Profile is Trapezoidal shaped, Light weight and wide Span. It is most economical and suitable solution for Mezzanine Flooring, Metal Deck Floor.

Roofing

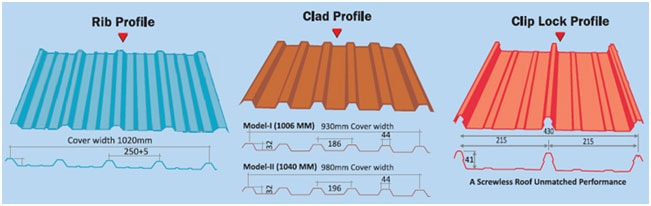

Single Skin Panels

It is a light weight, trapezoidal shaped roofing profile designed to take long span horizontal and vertical applications. Its aesthetic appearance makes it the most preferred profile by architects all over the world.

Insulated Sandwich Panels

Insulated Sandwich Panel is self supported. It is widely used for Cold Storages, Refrigerated Rooms, telecom Shelters etc and for insulation purpose in industrial and Commercial Cladding.

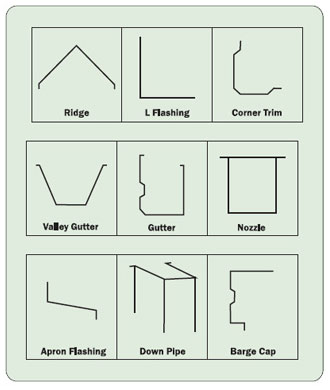

Trims and Flashing

Trims and Flashing include eave trim, eave gutter downspouts, gable trim, curved eave panels, flashing around building accessories, etc. Which are produced from prepainted aluzinc coated steel or aluminum sheets that are bent to the required shape using roll formers, presses, or folding machines. They weather seal the building and contribute to the neat finish appearance of a PEB. Building Accessories and special buyouts (SBO’s) include sliding doors, rollup doors, personnel doors, fiberglass insulation, sand trap louvers, windows, ridges ventilators. Some are produced in-house. Some are purchased from suppliers and included in our single source supply.

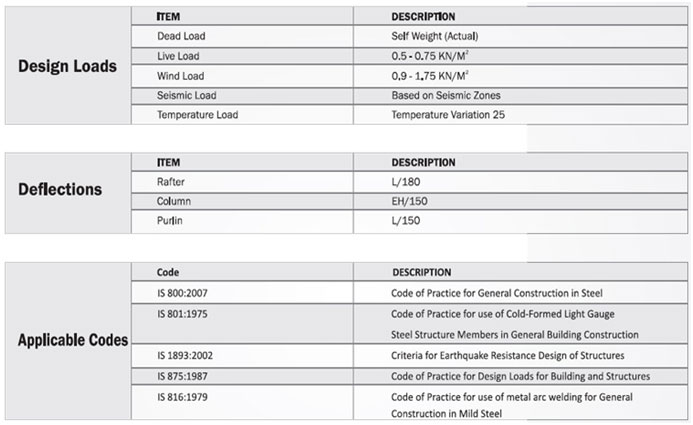

TECHNICAL DETAILS

With the help of advanced manufacturing techniques. world class manufacturing machinery and a technically sounf team. Our wide range of PEB structural systems makes building designing a flexible & economical exercise. While offering the exact look you require for your next project. We thus provide optimum & complete solutions to create a functional structure, as per your required standards, to meet your exact needs.

Product Gallery

PRODUCTS & SERVICES

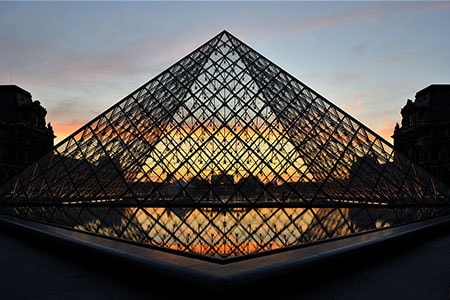

Airports

The integrated terminal buildings are designed with number of structural innovations. The key feature of airport structure is their long span roof covering with massive column spacing. The mega columns and large cantilevers make the structure unique. By using modular space frame structure supported by cantilevered columns makes the roof aesthetically good with doubly curved.

Learn More

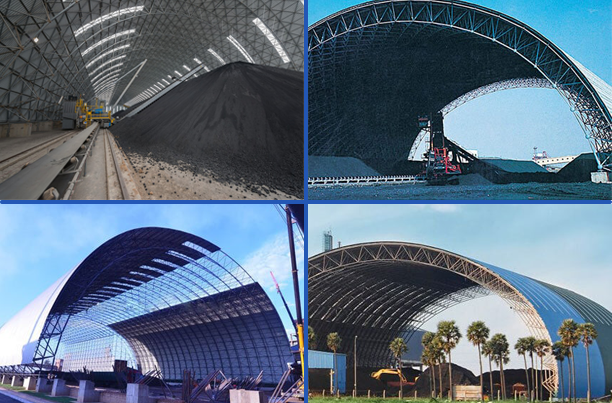

Bulk Storage Sheds

Bulk storage sheds are large span structure to accommodate tons of coals for continuous supply to the boilers.The structures are designed with modular space frame to make it cost effective compared to other conventional structures. Catwalks, ducts and other services can be accommodated within the top and bottom chords.

Coal

Space Frames

A space frame is a three-dimensional structure. The 3D behavior ensures optimum utilization of material. The quality of roofing is exceptionally good, as the deflections are almost negligible. Despite their light weight, these structures are designed to carry much heavier loads and have a huge spanning capacity. Erection time is minimal as the material is pre-fabricated from the factory.

Learn More

Multi-Storey Buildings

Steel frames construction is a very popular structural form for multi storey buildings as it provides great flexibility. The structure has adequate strength and stiffness to resist the applied loads due to gravity and wind. The function of the structure in resisting vertical loads due to gravity and horizontal loads due to wind is generally considered separately.

Learn More

Pre-Engineered Buildings

It offers a futuristic solution for creating durable and efficient structures in a cost-effective manner. Apart from great flexibility of designing and minimal construction time offered by PEB’s, they are also preferred for their robustness and durability. Moreover, it is possible to add a wide range of structural and non-structural components, which enhances their aesthetic appeal and also improves their usability.

Learn More

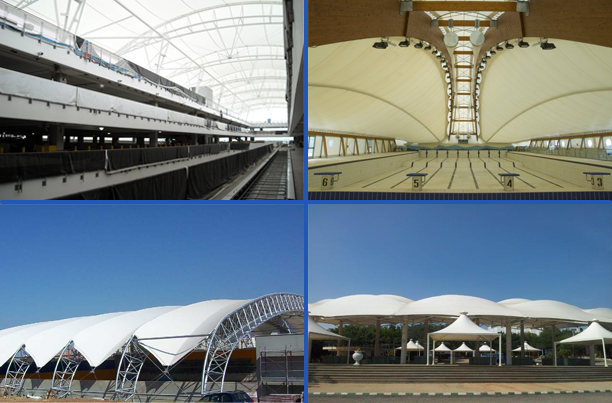

Membrane Structures

Textile supported by steel combines the high flexibility of use of this one, from reticular arches to infinite space geometries, with a singular covering applied only under optimum conditions in order to avoid abrasion and corrosion due to contact with the main bearing structure. The all-season use is guaranteed by a singular system of side opening in order to obtain maximum ventilation in the hot season.

Learn More

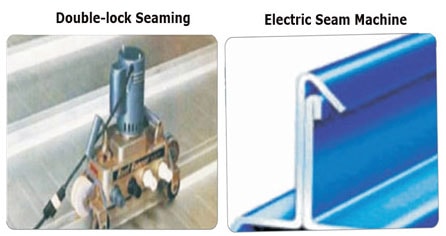

Self Supporting Roofs

A self-supporting roofing system makes it possible to erect a warehouse in one span without trusses, purlins, and rafters. The systems are mechanically sealed, which ensures better weather proofing and a hygienic and clean environment. The absence of holes, nuts, bolts, overlaps, or sealants, these structures require minimal to zero maintenance, making them highly cost-efficient.

Learn More